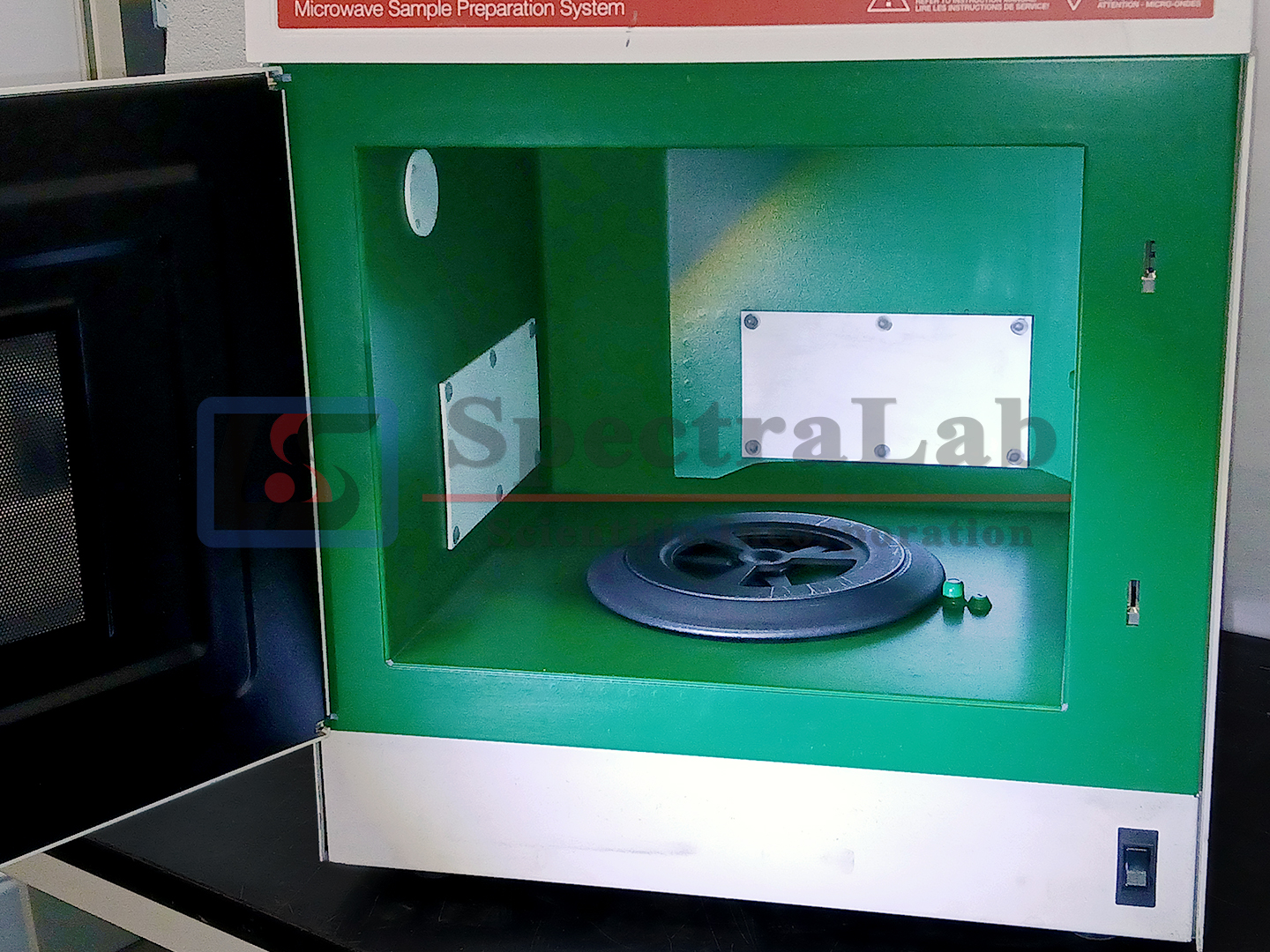

The PerkinElmer / Anton Paar Multiwave 3000 microwave system provides high performance, reliable quality and unrivaled safety, which is required in sample preparation in order to achieve superior analytical results. Multiwave 3000 is designed to bridge the gap between sample and analysis, whether you need wet acid digestion, solvent extraction or other special applications.

A modular microwave digestion system specially designed to considerably reduce the workload between sample collection and spectrometric analysis, major benefits of the Multiwave 3000 are its ease of use, safety and has quick handling. The reaction vessels, rotors and accessories are easily adapted to meet individual requirements for microwave sample preparation such as drying, evaporation, extraction, UV digestion or oxygen combustion.

Combining the benefits of a closed-vessel system with rapid microwave heating, Multiwave 3000 is a highly modular and therefore very versatile system which can cope with almost any sample preparation task:

- Acid leaching

- Acid digestion

- Microwave-assisted solvent extraction

- Evaporation (of aqueous solutions)

- Drying

- Microwave-induced oxygen combustion (MIC)

- Microwave-assisted UV digestion (MUV)

- Protein hydrolysis

Fields of Application:

- Environmental analysis

- Geochemical, mineralogical analysis

- Materials testing

- Food analysis

- Medical and pharmaceutical analysis

- Petrochemistry

- R&D and QC in the chemical industry

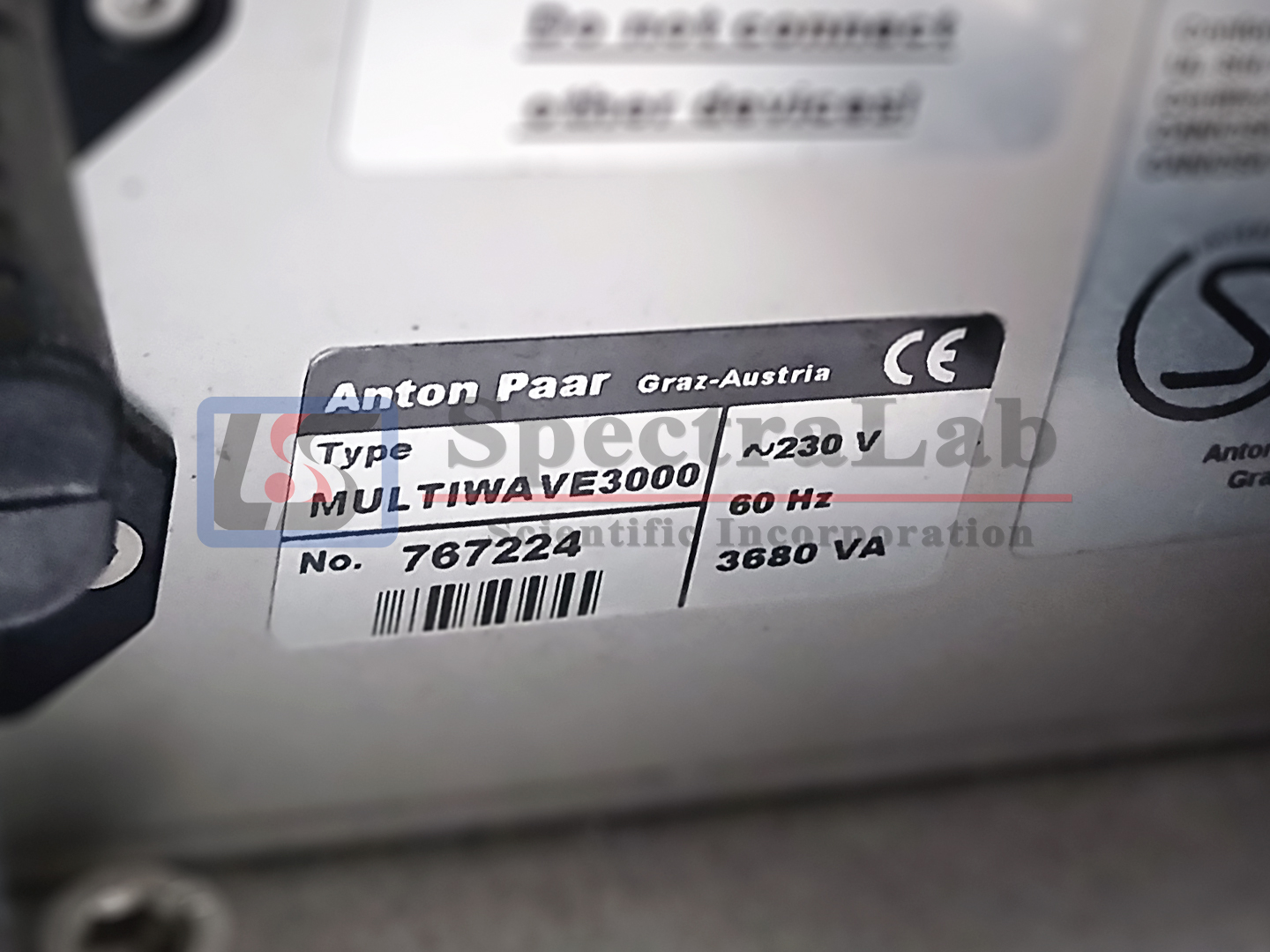

Specifications

Starting with a basic configuration, numerous accessories and options open the way for the perfect configuration based on customer needs.

- The 1400 W unpulsed microwave power from two magnetrons and advanced sensor technology ensure fast and homogeneous heating, perfect reaction control and an overall increased service life of the components.

- A proven safety system with active and passive devices minimizes the hazards from violent reactions.

- The cycle time is drastically reduced due to the easy handling of vessels, sensors and the patented vessel cooling. Neither external cooling, nor handling of hot pressurized vessels are required.

- High-performance digestions of up to 64 samples are possible with optional pressure and temperature control as well as leaching procedures such as USEPA methods. The 8-position rotor with simultaneous, active pressure control in all vessels ensures the utmost analytical performance in high-end applications.

- A unique feature among microwave systems, the microwave-assisted oxygen combustion in quartz vessels, supports sample preparation methods for nonmetal elements.

- Optimized temperature- and pressure-controlled closed vessel procedures provide microwave-assisted extractions within 10 to 20 minutes.

- Evaporation of acids and preconcentration of solutions can be performed directly from the reaction vessel under controlled clean room conditions.

- Unpulsed microwave control enables “soft”, efficient and short-time drying without carbonization or contamination of samples.